Modified ASTM E1105: Gravity Flow Test

What is the modified version of the ASTM E1105?

There are actually many modifications that can be done to the test method, but in general when professionals in the building industry are discussing a modified ASTM E1105 test it is usually in reference to conducting water penetration testing on fenestration products and the surrounding wall envelope at ambient field conditions. What that means is that there is no simulated wind load (Pressure Differential) being induced on a test specimen, which is a step detailed in the full version of the ASTM E1105 test method.

What is the Gravity Flow Test?

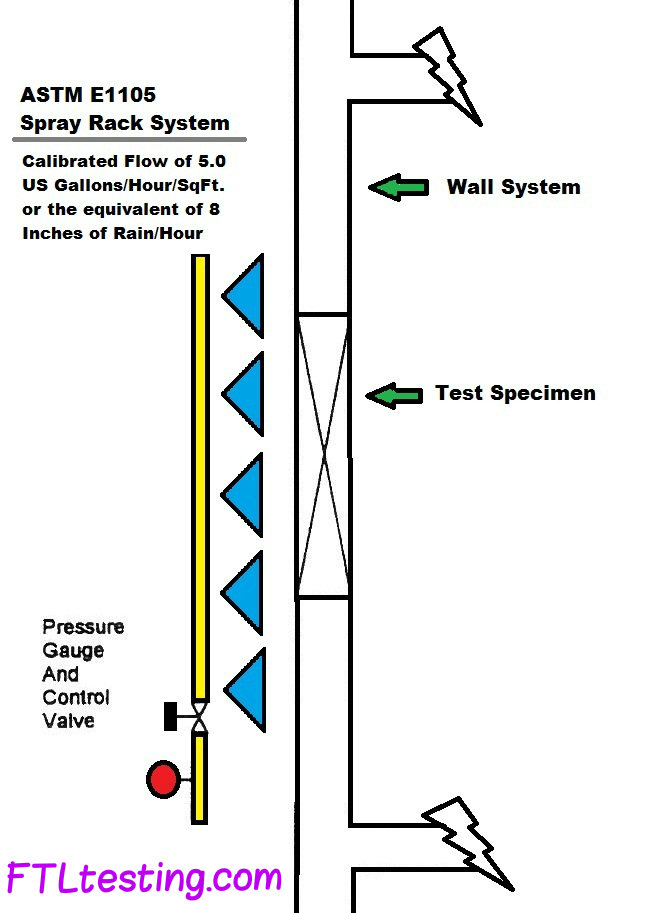

It is simply another name for the modified version of the ASTM E1105 test method. The name originates from the fact that gravity is naturally working upon the water flow that a spray rack system is dispensing over a test location. An additional name that is also sometimes used is the Spray Rack test since only the spray rack system is being utilized. It's important to note the different names that may be called out on construction job sites, but all typically refer to the same thing.

Why is the Gravity Flow Test used?

The modified version of the test is used in the building industry because it is an excellent quality assurance check for water penetration resistance on new construction projects as well as a valuable tool for Forensic Investigators that are attempting to replicate and trace the source of known leaks through the building envelope.

The gravity flow test is often used on new construction sites where standard pressure differential testing may be an impractical option to test very large areas of the building envelope that may include windows, doors, and wall systems.

Quicker set-up times also allow for gravity flow testing to maximize test production that would not otherwise be possible or practical if only pressure differential testing was being utilized.

Why is the set up time quicker with the Gravity Flow Test?

Standard pressure differential testing, or the full version of the ASTM E1105, requires that test chambers be built and set-up onsite in order to simulate a wind load; time is spent fabricating the chambers, prepping the test areas, and mounting the test chambers as well as setting up the spray rack system on the exterior of a given test location.

Due to the fact that only the spray rack system is being used in gravity flow testing time is saved by eliminating the time lost in chamber fabrication and set-up.

Is the Gravity Flow Test still a good and valid Quality Assurance test without the wind load being simulated?

In terms of functionality and actual test results most building professionals would say yes, but there are of course always exceptions for certain situations. The main reason the test is valued as a quality assurance test in the building industry (for newly installed products and systems) is because the rate of water being dispensed over a test location is still very extreme and goes above and beyond the highest recorded rainfall event in a one hour period in the contiguous United States, which is less than 5 inches (flow rate of the spray rack system for gravity flow testing is not less than 5.0 US Gallons/Hour/Square Foot or the equivalent of 8 inches of rain per hour). It is generally accepted that if there are inherent weaknesses within a fenestration product and/or wall envelope system, that the gravity flow test will assist in discovering such potentially problematic locations.

Every job will have its own set of challenges and unique circumstances, so it is a good idea to consider job site conditions, project specifications, and input from all interested parties before commencing with any type of testing.

Diagram - Gravity Flow Test (Modified ASTM E1105)